Advantages Of Stainless Steel Fabrication

March 27, 2023

Introduction To Stainless Steel

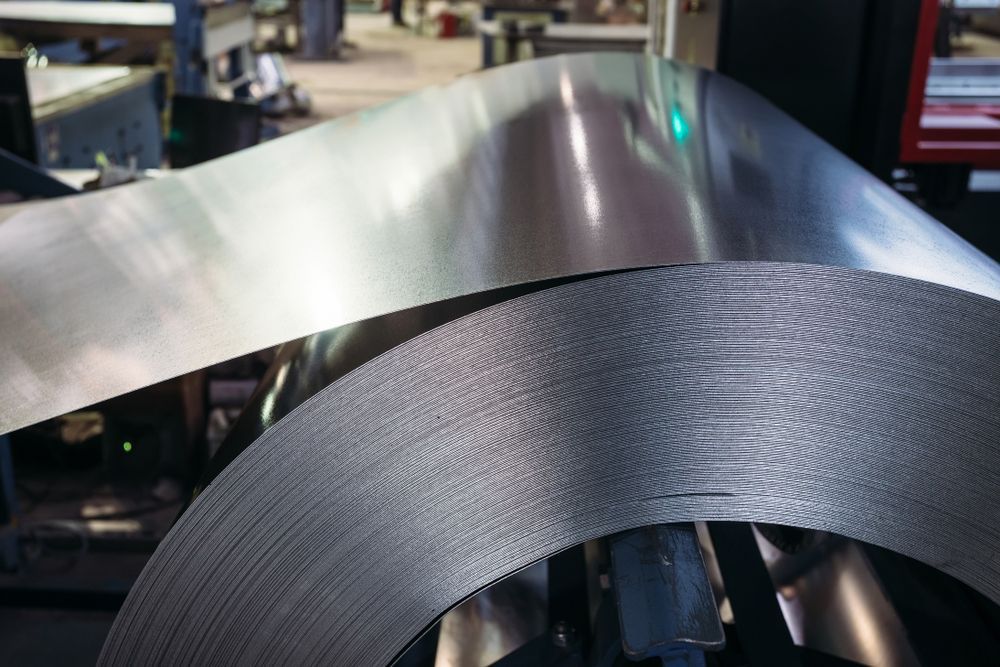

Stainless steel is a popular material in various industries due to its unique properties, making it suitable for a wide range of applications. It’s an alloy of iron, chromium and other elements, with varying compositions depending on the intended use. Stainless steel is known for its corrosion resistance, durability and strength, ideal for use in harsh environments where other materials may fail.

Stainless steel is also favoured for its aesthetic appeal, with its shiny surface finish and smooth texture making it a popular choice for architectural designs and decorative applications. Additionally, it’s non-reactive and non-magnetic, which is safe for use in sensitive applications such as medical equipment and food processing.

What Is Stainless Steel Fabrication?

Stainless steel fabrication is the process of transforming raw stainless steel materials into finished products through cutting, shaping, welding and other methods. It involves the use of specialised equipment and techniques to create products that meet specific design and performance requirements.

Stainless steel fabrication can be used to create a wide range of products, from small components such as bolts and nuts to large structures such as bridges and buildings. Some of the most common products created through stainless steel fabrication include tanks, pipes, valves, fittings and architectural components such as handrails and balustrades.

Advantages Of Stainless Steel Fabrication

Stainless steel fabrication refers to the process of shaping stainless steel into different forms, such as sheets, pipes and wire, through cutting, bending, welding and other methods. This process has several advantages, which include:

Durability And Longevity

Stainless steel is known for its exceptional durability, as it can withstand harsh environmental conditions such as extreme temperatures, moisture and chemicals. Stainless steel also has a high resistance to corrosion, rust and staining. These qualities ensure high performance in outdoor applications, such as construction, marine and automotive industries, where durability is a top priority.

Aesthetic Appeal

Stainless steel is a highly versatile material, which makes it an excellent choice for decorative and architectural applications. It has a sleek, modern look that can add a touch of elegance and sophistication to any space. Stainless steel can also be polished or brushed to achieve different finishes, giving it a unique appearance that can complement just about any design.

Hygienic Properties

Stainless steel is non-porous, which means it’s resistant to bacteria, germs and other microorganisms. As such, it is an excellent material for use in medical equipment, food processing and pharmaceutical industries, where hygiene is critical. Stainless steel is also easy to clean and maintain, offering a low-maintenance option.

High Strength And Resistance

Stainless steel has excellent mechanical properties, such as high strength and toughness, making it ideal for use in heavy-duty applications. It also has a high resistance to impact and vibration, which makes it a popular choice for structural components and machinery.

Sustainable Material

Stainless steel is 100% recyclable, allowing the material to be reused without losing its properties. Recycling stainless steel reduces waste and conserves resources — it's an environmentally friendly option. Additionally, stainless steel fabrication processes use less energy than other materials, so it’s also a fantastic energy-efficient choice.

Get In Touch

HardRok Engineering offers

heavy fabrication services to clients throughout Northern Queensland and the Northern Territory. Our team of engineers have the experience and expertise to deliver quality fabrication solutions that meet the unique requirements of our clients. So what are you waiting for?

Contact us today for all your stainless steel fabrication needs.