How Does Custom Steel Fabrication Support Sustainability?

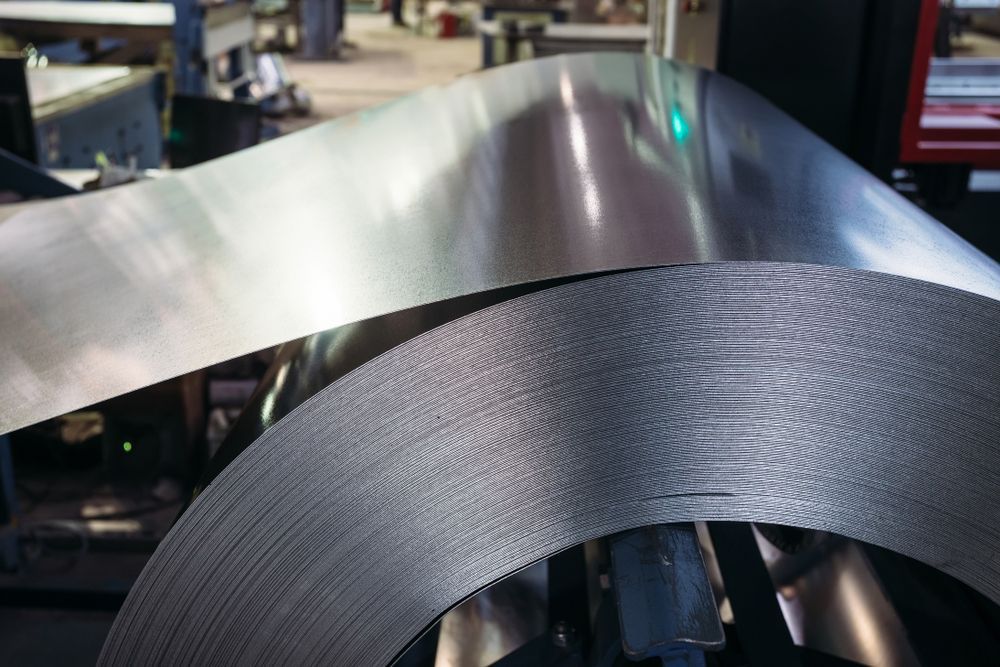

The Role of Material Efficiency in Custom Steel Fabrication

Material efficiency is more than just a trendy phrase; it's a crucial approach in the engineering field. By using state-of-the-art machinery like CNC Plasma Dual Head Cutting Machines, engineers can significantly reduce waste. These machines offer high precision in cutting, which minimises excess material and, as a result, contributes to more sustainable practices in steel fabrication.

Energy-Saving Innovations in Steel Production

When it comes to steel production, energy efficiency is a game-changer. Innovative technologies are not only enhancing the quality of the end product but also reducing the environmental impact. Here are some key ways these advancements are making a difference:

- Cleaner Edges : Energy-efficient plasma cutting produces cleaner edges, reducing the need for further processing. This also means less energy is consumed in additional refining steps.

- Smaller Holes : The technology can cut smaller holes, which means less material and energy are used. Smaller holes also translate to lighter materials, further contributing to energy savings.

- Thicker Materials : Plasma cutting can handle thicker materials, making it versatile and reducing the need for multiple machines. This versatility eliminates the need to switch between different machines, saving both time and energy.

The Lifecycle Approach to Sustainable Steel Fabrication

When it comes to sustainability in steel fabrication, it's essential to look at the entire lifecycle of a product. From the materials used to how the product is eventually disposed of, each stage offers opportunities for eco-friendly practices:

Sourcing Raw Materials Engineers consider the source of the steel used in fabrication. Opting for recycled or sustainably sourced steel is the first step in a sustainable lifecycle.

Disposal At the end of a product's life, the focus shifts to recycling. Steel is highly recyclable and engineers design products to be easily disassembled for this purpose.

Balancing Cost and Sustainability: Is It Feasible?

Take the Next Step Towards Sustainable Engineering

If you're looking to make your next project both high-quality and sustainable, look no further. At HardRok Engineering, we're committed to offering quality custom steel fabrication services. Our team of engineers uses the latest technology to ensure your project is a success on all fronts. Reach out to us through today! Let's work together to build something great and green.