What Is The Difference Between Steel Fabrication Vs Metal Fabrication?

Have you ever found yourself wondering whether your project requires steel fabrication or metal fabrication? It’s a common question that can easily leave anyone puzzled, especially when both terms are often used interchangeably. While steel is indeed a type of metal, there’s more to fabrication than meets the eye. Understanding the distinctions between steel and metal fabrication can help you make informed decisions for your project needs.

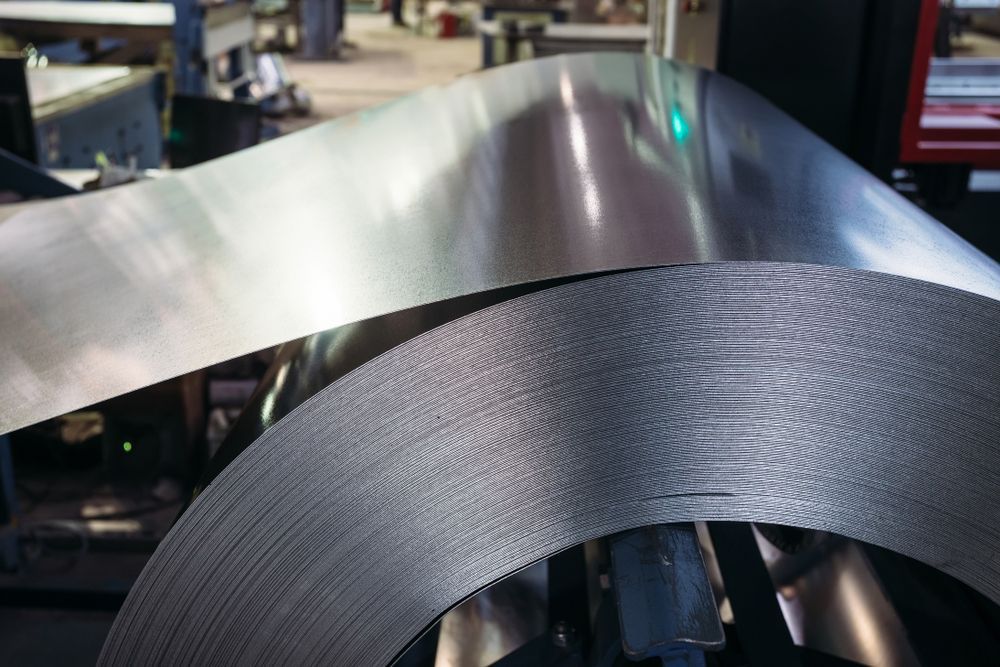

Understanding Steel Fabrication

Due to its consistent properties, steel fabrication is relatively straightforward. Steel can be welded, bent and moulded into various shapes, allowing fabricators to create precise and robust components. Steel fabrication offers reliability and longevity, Whether for construction or custom-designed products.

What Is Metal Fabrication?

For instance, aluminium is lightweight and resistant to corrosion, making it suitable for projects requiring ease of transport and installation. Copper, known for its conductivity, is often used in electrical applications. Metal fabrication requires a deep understanding of each metal’s properties and specialised techniques to achieve the desired results.

Key Differences Between Steel Fabrication & Metal Fabrication

Steel fabrication often involves welding, cutting and bending—processes that are straightforward due to steel’s uniform properties. In contrast, metal fabrication might require more specialised techniques to handle different metals’ behaviours under heat or pressure.

For example, welding aluminium requires a different approach than welding steel due to aluminium’s tendency to crack and warp.

How Do These Differences Impact Your Project?

Contact Us For Tailored Fabrication Solutions

While steel fabrication and metal fabrication share similarities, their differences lie in the materials used and the required techniques. Choosing the fabrication type that best suits your needs is crucial for your project’s success. At

Hardrok Engineering , we provide custom steel fabrication and offer professional guidance to help you determine whether steel or another metal is best for your needs. Our commitment to quality and precision ensures that your project receives the highest level of craftsmanship.

Consult with us today to explore the best fabrication options for your next project.