How To Save Money On Custom Steel Fabrication

In the dynamic world of custom steel fabrication, cost efficiency is as important as the quality of the final product. Whether you're a business owner looking to invest in robust infrastructure or an individual seeking bespoke steel pieces, understanding how to save money without compromising on quality is key. This blog post explores the world of custom steel fabrication, exploring various strategies and innovations that can lead to significant cost savings.

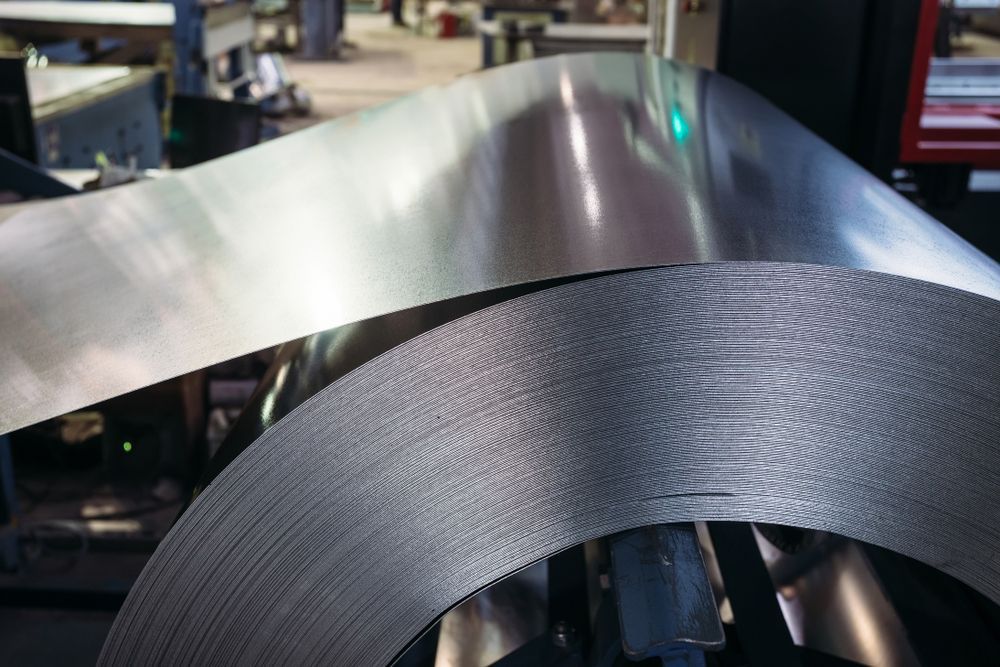

Exploring Cost-Efficient Materials in Steel Fabrication

Let's explore how selecting the right materials and embracing innovative solutions can lead to significant cost savings without compromising on quality:

Choosing the Right Material

- Cost vs. Durability: Balancing the cost of materials with their durability is important. Opting for cheaper materials might save money upfront but can lead to higher maintenance and replacement costs in the long run.

Innovative Material Solutions

- Recycled Steel: Utilising recycled steel not only reduces costs but also supports environmental sustainability.

- Lightweight Alternatives: Exploring lighter materials can reduce transportation and handling costs.

Can Efficient Project Management Reduce Fabrication Costs?

In addition to these core strategies, efficient project management in custom steel fabrication also involves proactive problem-solving and adaptability. Anticipating potential challenges and being prepared with solutions can prevent costly delays. Furthermore, leveraging data-driven insights for continuous improvement helps in refining processes and reducing costs over time.

Proven Strategies to Cut Costs in Custom Steel Fabrication

- Leverage Advanced Technology: Utilising state-of-the-art machinery, like CNC plasma dual-head cutting machines, enhances precision and reduces waste.

- Optimise Design: Computer-assisted design (CAD) can streamline the fabrication process, minimising errors and material wastage.

- Bulk Purchasing: Buying materials in bulk can lead to significant cost savings.

- Preventative Maintenance: Regular maintenance of machinery prevents costly breakdowns and delays.

- Skilled Workforce: Investing in skilled labour ensures efficiency and quality, reducing the need for reworks.

Overcoming Budget Overruns with Innovative Fabrication Techniques

Adopting innovative fabrication techniques is important to tackle the challenge of budget overruns. These methods offer a pathway to reduce costs while maintaining high standards of quality and efficiency.

Precision Cutting with CNC Plasma

- Enhanced Accuracy:

CNC plasma cutting offers unparalleled precision, reducing material wastage and labour costs.

Innovative Welding Techniques

- Efficient Processes:

Advanced welding techniques contribute to faster turnaround times and lower labour costs.

Connect with HardRok for Custom Steel Fabrication

At HardRok, we're committed to delivering custom steel fabrication solutions that align with your specific needs and budget. Our team combines expertise with innovative technology to ensure every project is a testament to quality and efficiency. If you're looking for reliable and cost-effective custom steel fabrication, we're here to help. Get in touch with us through our contact page or give us a call. We're ready to discuss your project, offer insights and provide the high-quality service you expect. Let's work together to turn your ideas into reality with precision and care.