Types Of Steel Used In Welding And Fabrication

When you're starting a project that involves welding and fabrication, the type of steel you choose can make or break the outcome. It's like selecting the right ingredient for a recipe; the end product depends heavily on what you start with. This is why understanding the various types of steel and their applications is very important. In this blog, we’ll discuss the different types of steel used in welding and fabrication projects in Mount Isa, as well as their various applications and benefits.

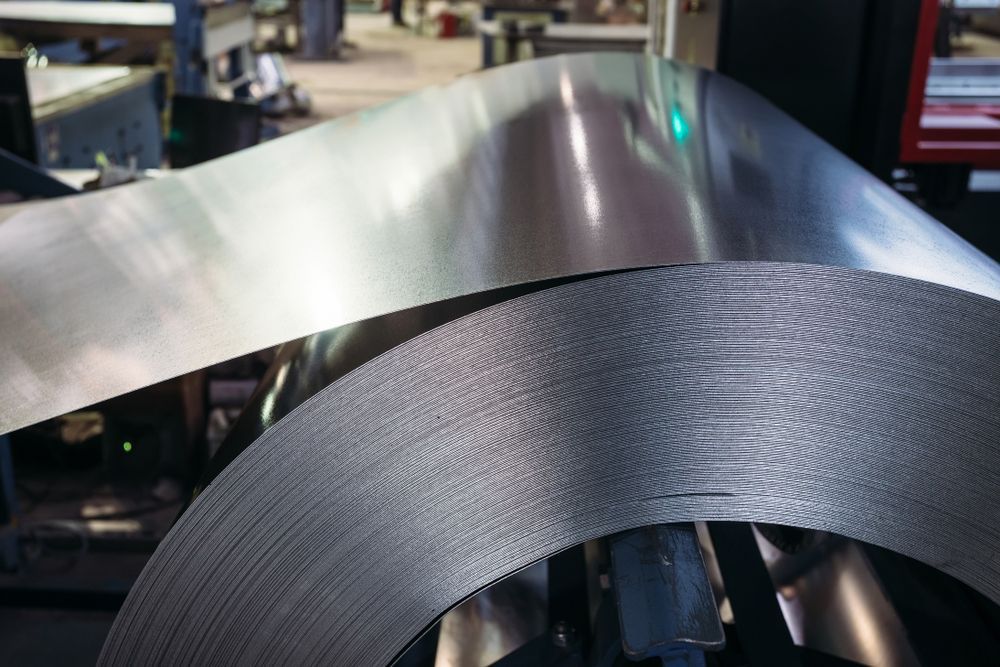

The Backbone Of Industry: Steel's Role In Fabrication And Welding

Exploring The Spectrum: Different Types of Steel For Diverse Applications

- Carbon Steel: The workhorse of the industry, known for its balance of durability and affordability.

- Alloy Steel: Enhanced strength and wear resistance for more demanding applications.

- Stainless Steel: The go-to for corrosion resistance, ideal for harsh environments.

- Tool Steel:

Hardened to withstand abrasion and deformation, perfect for cutting and drilling equipment.

Material Matters: Selecting the Right Steel for Your Project

Choosing the correct type of steel is a pivotal decision in the fabrication process. It's not just about the material's cost or availability; it's about how well it aligns with the project's specific needs. Factors like environmental conditions, stress levels and exposure to chemicals play a significant role in this choice. The right type of steel ensures the project's functionality and enhances its longevity.

Steel Selection: A Path to Achieving Desired Engineering Outcomes

The process of selecting steel is both an art and a science. It requires a deep understanding of material properties and a clear vision of the project's goals. Here are some considerations to guide the selection:

- Project Requirements: What are the mechanical and environmental stresses the steel must withstand?

- Material Properties: How do the strength, ductility and corrosion resistance of steel match your project's needs?

- Cost-Effectiveness: Is the steel choice economically viable without compromising quality? Balance initial costs with long-term value, considering maintenance and lifespan.

- Fabrication Process Compatibility:

Verify that the steel can be effectively processed with your available fabrication methods, including cutting, welding and finishing techniques.

Elevate Your Fabrication Project: Reach Out To Us!

At HardRok Engineering, we understand the critical role steel plays in welding and fabrication projects. Our expertise in custom steel fabrication in Mount Isa ensures that every project we undertake is built on a foundation of quality and precision. We offer specialised steel fabrication engineering solutions tailored for the mining, construction, processing and heavy industries. With a strong commitment to safety and efficiency, our team delivers quality work. If you're planning a project that requires professional welding and fabrication services, get in touch with us.