Why Quality Control is Important in Steel Fabrication

Steel fabrication is essential in constructing durable and resilient buildings, bridges, and other large structures. Ensuring quality control throughout the fabrication process is not just about meeting industry standards; it’s about enhancing safety, prolonging lifespan, and ensuring each component performs as intended. In this blog, we’ll explore why quality control is so critical and how it impacts structural integrity, durability, precision, and project efficiency.

Enhancing Durability & Longevity

Quality control in steel fabrication also plays a crucial role in maximising the lifespan of steel structures. With proper oversight, steel components can last for decades, even under challenging environmental conditions.

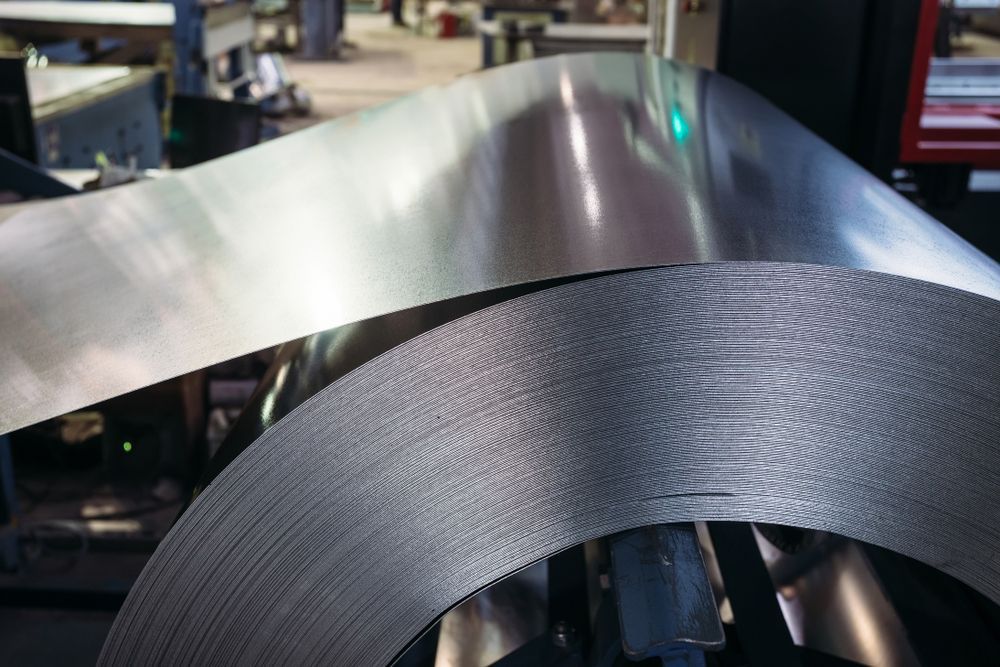

- Surface Treatments for Protection: Coatings, such as galvanisation, protect steel against rust and corrosion, essential in harsh climates. These treatments are checked rigorously to ensure thorough application, giving each component extra resistance to environmental damage.

- Material Quality Checks: Quality control includes verifying raw materials to confirm they meet required strength and durability specifications. This step helps prevent early wear and tear.

- Corrosion Resistance: Ensuring each component has adequate corrosion resistance is particularly critical in industrial or coastal areas, where exposure to moisture and salt air can accelerate deterioration.

Precision in Fabrication & Fit

Precision is another vital element in quality steel fabrication. Precise measurements and attention to detail are required to ensure that every component fits exactly as intended, supporting the overall integrity of the structure.

- Advanced Measurement Techniques : Quality control teams use sophisticated measurement tools to ensure every piece is fabricated to exact specifications so that when the steel components are assembled, they fit perfectly and perform reliably.

- Consistent Welding Standards : Welding is crucial in steel fabrication, and high-quality welding practices are essential for maintaining component strength. Regular checks ensure that welds are consistent, robust, and free from defects, which is especially important in high-stress areas.

- Minimising Adjustments During Assembly

: By maintaining strict quality standards, fabricators ensure fewer adjustments are needed during the assembly, saving time and costs.

Experience the Highest Standards in Steel Fabrication with HardRok

At HardRok, we excel in providing custom steel fabrication for mining, construction, and industrial projects. Our team prioritises safety, precision, and efficiency, ensuring that every component meets the highest standards of strength and durability. Whether you need heavy fabrication or general engineering, our team is here to help. Contact us today to discuss your fabrication needs in Mount Isa and experience our commitment to excellence firsthand!