How Steel Fabrication Is Used In The Mining Industry?

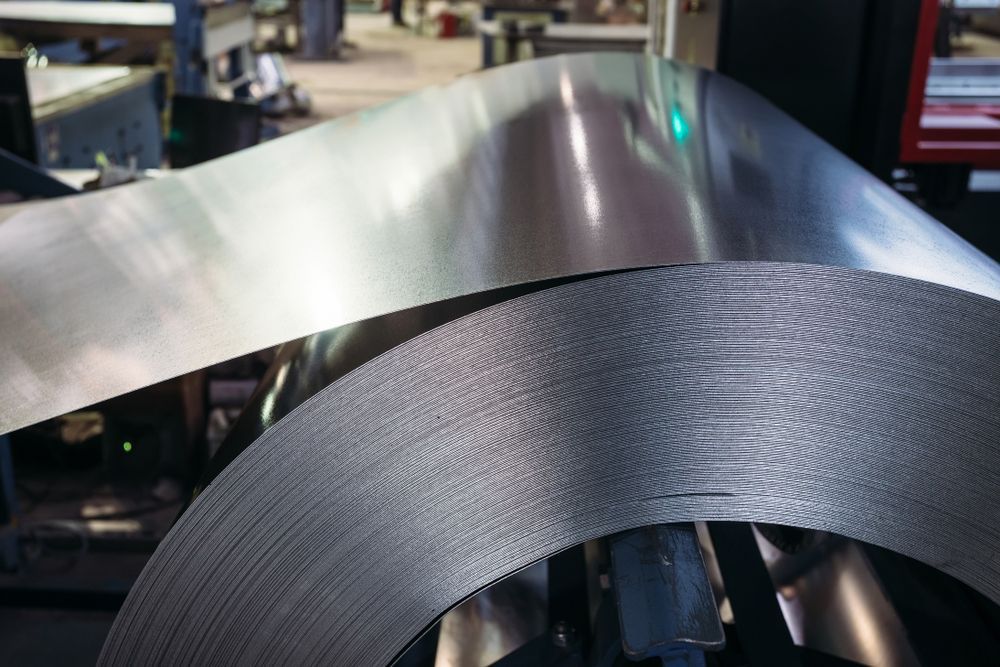

Since steel is such a versatile material, it is ideal for applications that require custom design as it can be bent or moulded in many different ways without losing any of its durability.

It is an essential material for the construction industry, automotive manufacturing, for the infrastructure required to generate and distribute energy and many other sectors ranging from household appliances to shipbuilding. It is also a vital cog of the mining industry.

Today, steel is used in every aspect of Australia's mining industry - the very mining infrastructure itself is constructed using steel structural frameworks. In this article, we outline why steel fabrication is essential for all mining operations.

Steel Is Strong Enough To Withstand Harsh Mining Conditions

In most instances, mining operations are established in some of the harshest weather conditions in Australia so all infrastructure needs to be able to withstand searing heat, freezing nighttime temperatures, dust and sand storms and even hail and flooding.

Steel possesses the essential tensile strength and durability to stand up to these extreme conditions at mining sites in the Australian outback.

It Is A Versatile Solution For A Wide Range Of Mining Applications

Steel is by far the most common metal in the mining industry because of its benefits and properties, such as its low cost, strength, light weight, resistance to corrosion, durability, and sustainability.

With computer-aided design technology, steel can be manufactured with greater efficiency and precision than ever before, which means that it is used for advanced pieces of equipment that contribute to mining, including:

Vehicles and Machinery : Including bulldozers, crushers, excavators, drill rigs, front end loaders, surface feeder-breakers, track loaders, trucks, graders and much more.

Tools : Steel is an essential material for manufacturing necessary tools like shovels, grinding equipment, demolition equipment and various handheld and machinery-installed devices.

Infrastructure : Including tanks, pipes, vessels, boilers, screens, stairs, handrails, elevators, mine cages,

conveyor belts and even basic workplace essentials like workbenches and doors.

Equipment

: like high-strength plates, pumps, screens, filters, augers, blades, hammers, rippers and more.

To Protect Workers Underground, Structures Made Of Fabricated Steel Are Used

Ensuring a safe work environment and preventing work-related injuries or worse is as vital as it is challenging when dealing with underground mining operations. To protect workers underground, structures made of fabricated steel are used. Underground mine workings must have strong, rigid, flexible supports that meet the required technical requirements and fabricated steel ticks all boxes.

Located in Mount Isa,

HardRok Engineering provides fabrication and welding services for many heavy industries, including mining.

Our

experienced team can install, repair, maintain, and modify machinery and equipment throughout North West Queensland and Tennant Creek in the Northern Territory.

For more information,

contact HardRok Engineering on

(07) 4749 1770.