Why is Using Stainless Steel So Common? | Hardrok Engineering

What is metal fabrication?

Different metal fabrication methods

- Grinding

- Shearing

- Welding

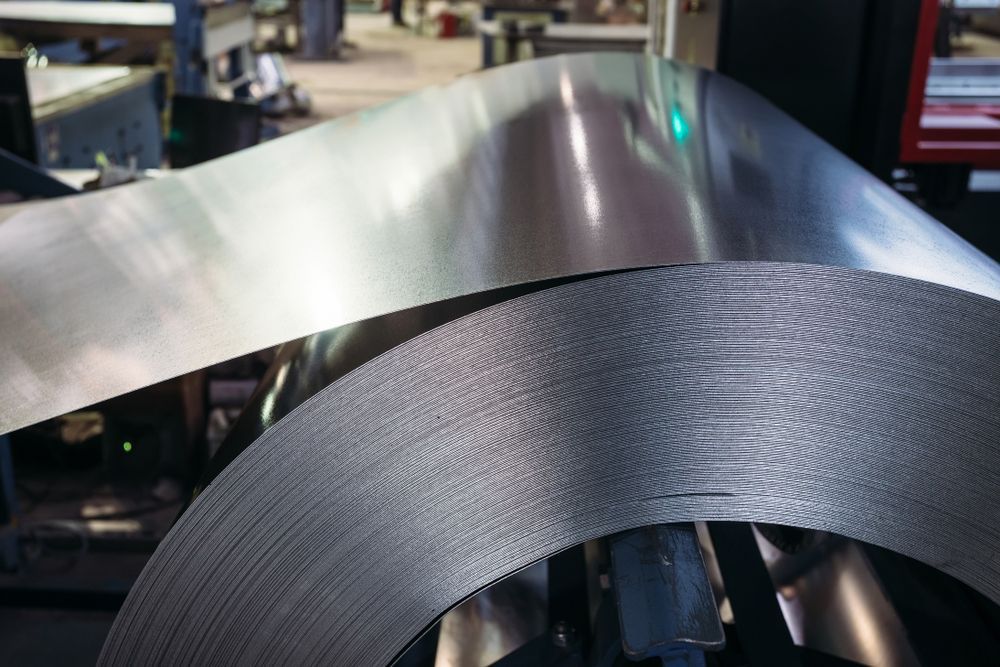

- Rolling

How does metal fabrication work?

Metal fabrication is a value-added process as it shapes metal into a useful design. Metal fabrication involves several key steps.

First is the planning stage. Engineers, designers and fabricators must decide exactly what they want the finished product to look like and how this will be achieved.

They must decide which tools will be used and whether computer programs will be necessary. Raw materials such as fittings and castings may need to be ordered at this stage.

The next step is production, the success of which depends on the accuracy of the planning stage.

The metal will first be cut and formed using punches or die. A rolling machine may be used to round certain parts of the metal.

When these basic tasks are completed, the pieces will be assembled to create the final product.

Individual fabricated components are welded together to form the larger product. Any finishing touches will be added so that the product passes inspection.

When completed, the fabricated metal will be assessed by assurance professionals to check that it is safe and fit for purpose.

At Hardrok Engineering, we provide metal fabrication in Mount Isa for the mining and construction industries.

Our workshop is fully equipped for steel and aluminium cutting, welding and general fabrication. Contact us today to learn more.