Steel Fabrication For Conveyor Systems

July 16, 2021

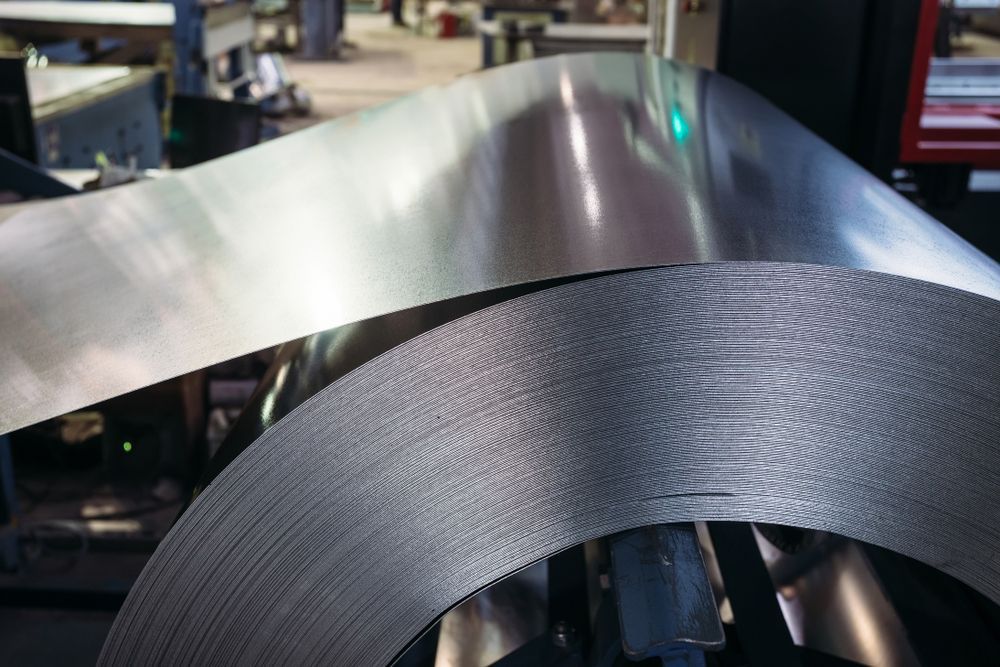

Custom Steel Fabrication For Conveyor Systems

Metal fabrication is required to produce high-performing and industry-specific material handling equipment. Our conveyor system fabrications are applicable to multiple industries, including manufacturing, postal, construction, and publishing.

We use a variety of steel fabrication techniques to ensure that your conveyor system complies with your business needs, whether it be packing or loading equipment. Some processes we use include:

- CNC machining

- Welding

- Small and large-scale rolling and forming

Whether you require a custom fabrication or need to adapt your pre-fabricated conveyor system, HardRok Engineering is more than qualified to help. We will ensure that the finished product supports your business operations and enhances workflow.

Give us a call today on 07 4749 1770 for more information.

A Wide Range Of Conveyor Systems Made Possible With Our Steel Fabrication Services

There is a wide range of conveyor systems that metal fabrication can facilitate. These include:

Cross-belt Conveyor Systems

Looking for a high-speed sorting system to which can perform multiple functions simultaneously? Then a cross-belt conveyor system may be for you. The belt is stretched across two or more pulleys and forms a loop around them – allowing it to continually rotate.

This system is ideal for sorting a wide variety of small items, including postal services. It can also be easily integrated into existing conveyor systems at low operating costs. This makes it a suitable option for customers looking to add to a pre-fabricated conveyor system.

Tilt Tray Conveyor Systems

HardRok Engineering can also fabricate tilt tray conveyor systems. Trays are connected to form a chain and are tipped to slide objects into a chute. They offer noiseless operations and require minimal maintenance.

This conveyor system is beneficial for multiple industries, including:

- Retail

- Publishing

- Parcel-courier

- Electronics

-

Clothing

Pop-up Belt Conveyor Systems

Opt for a conveyor system that allows for seamless integration and variable speed settings. Pop-up belt conveyor systems lift an item vertically before manoeuvring it to another conveyor at a 90° angle.

If you’re unsure what conveyor system to employ, we recommend this. You can choose between chain fabrications or rubber belts, and they also offer various construction types, such as non-contact product spacing.

We also offer pop-up roller systems and linear sliding shoe conveyor systems. To find out more about how our steel fabrications can facilitate your transfer systems, get in touch with us today.

Why Choose Us?

HardRok Engineering considers all metal-conveyor steel fabrications as an end-to-end process. This means we don’t layer materials that allow for swift movement and high performance. We consider all individual components, from the belt and pulleys to drums and gearbox, to ensure that the finished product works seamlessly.

You should choose us for all steel fabrication jobs on your conveyor system because:

- Over 45 years of experience

- Local family-owned business

- We support local suppliers

- Bespoke service

- Quick response team available 24/7

If you require steel

conveyor maintenance or other steel fabrication services in Northwest Queensland and Northern Territory,

contact our team today.