Steel VS Aluminium in Sheet Metal Fabrication

Sheet metal fabricators work with a range of metals and alloys to create a wide variety of components. Two materials that are frequently used to create everything from boats to bridges, houses, and machines are steel and aluminium. Here we take a closer look at the characteristics of each, as well as determine those applications that are best suited to steel and those that will give the best results when aluminium is used.

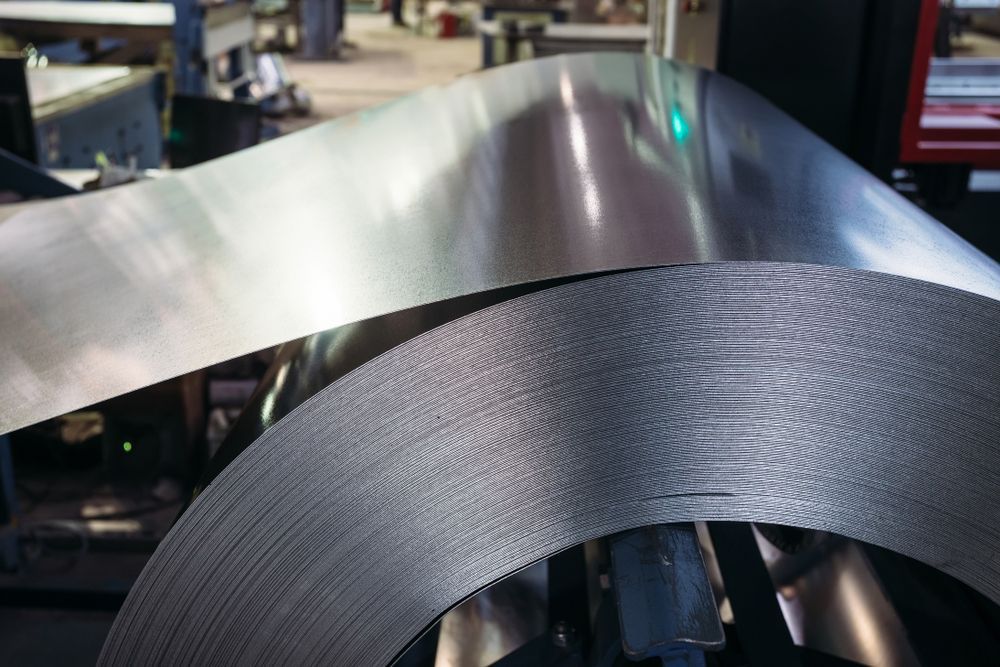

Steel

In general, steel is going to be heavier than aluminium. Weight can add stability to structures, as well as act as a beneficial crushing force (such as in rolling machines) in some circumstances. Steel is also enormously strong - most types of steel are far stronger than aluminium. If you want a material that can take a beating without bending or distorting, steel is ideal.

Unfortunately, steel also has a tendency towards brittleness. This can make it difficult to shape - if force is applied in the wrong direction it can easily snap. For this reason, it's important to use experienced fabricators for your steel project - they can advise on the best type of steel to give you the results you need.

Aluminium

Aluminium lacks the strength of steel, and its malleability may be a disadvantage in projects where unwanted distortion is a risk. It's a better conductor than steel - this may be an advantage or disadvantage, depending on the project type. Like steel, it can also corrode in salt water, but won't rust. Because pure aluminium is highly reactive, aluminium is usually mixed with zinc or some other metal to stabilise it before it's used in fabrication.

Aluminium VS Steel: Which One is Going to Work Best For My Project?

Ultimately the answer to this question depends on the nature of your project. Based on your project specifications, an experienced fabricator can determine what type of aluminium or steel alloy is going to give the best results. If cost is a consideration, it's possible to make savings by buying aluminium or steel when the price is low - fluctuating markets for both materials mean it's likely you can pick up a bargain, no matter what choice you make.

The time-served, knowledgeable fabrication

team

at

Hardrok Engineering can provide further information about the best material for your intended fabrication project.

Contact us on

07 4749 1770 today!