Steel is an alloy metal, considered by many to be one of the most important materials for use in construction.

It is a versatile, hard-wearing metal, and used in everything from washing machines and cars to bridges and skyscrapers.

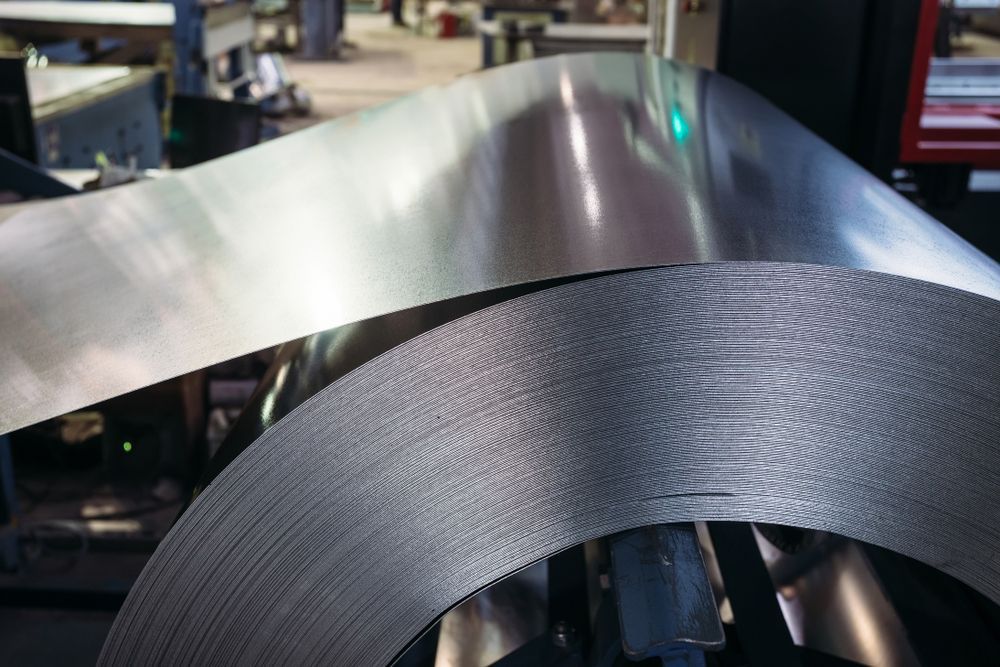

The steel fabrication process involves cutting, bending, or shaping raw steel to create the required product.

At HardRok Engineering, we focus on large item

fabrication in Mount Isa to support the mining, quarry, and farming industries and take pride in having an extensive workshop which we are constantly expanding to better meet our clients' needs.

Design

Designing the product or part to meet your needs is the first step.

At HardRok Engineering, our ‘One Stop Shop’ policy means we offer you custom designs, as well as production.

We work with you to ensure a perfect design for your requirements.

The final designs are then converted into blueprints or workshop drawings to begin fabrication.

Cutting and drilling

Once a design is finalised, our expert team in Mount Isa can begin work.

The steel is first cut or drilled to size. Our workshop is equipped with a variety of cutters and drills, which can be used on different grades of steel and aluminium.

If surface preparation is required for painting later, this will be done as well.

Bending and shaping

Some projects, including tunnels or machine parts, involve a curved shape, while others require sharp angles.

Rollers and metal presses in our workshop are used to shape your project, while lathes and mills can be used to refine the project more precisely.

Welding and assembly

When all of the parts of your project have been completed, our qualified welders can begin assembly.

Welding uses extremely high heat to create a melted portion of the metal, and as it cools and hardens, a join is created.

Welding is used to attach connections that may be needed for installation, or to connect individual components of a larger product. Our workshop offers MIG, TIG, and Stick welding facilities.

Final touches

Before leaving our workshop, your project is carefully inspected to confirm we have met your requirements and have provided you with quality work.

If necessary, painting and

rubber lining

can also be performed at this stage.

Installation and commission

Once your project has received the seal of approval at our workshop, we also offer on-site installation and commission to ensure seamless handover of your new project.

Commissioning involves confirming the project has been correctly installed and is operating as expected.

Customer service

Perhaps the most important step in the process is ongoing customer service. We offer 24/7 emergency repairs and assistance. Our

Site Service vehicles are suited to 4WD and mine access and are equipped with welders, cranes, and other repair facilities.

HardRok Engineering is proud to service Mount Isa, Tennant Creek and surrounding areas, helping to create jobs and support some of Australia’s most important industries.

Contact us today to find out how we can help you with your next steel fabrication project.