What Does A Steel Fabricator Do?

February 17, 2022

Steel fabricators are highly skilled professionals that work in the manufacturing and construction industries, but what does a steel fabricator actually do, and what skills do they have? Let's take a look.

What Does A Steel Fabricator Do?

The role of a steel fabricator will vary depending on the company they work for, but they are primarily responsible for cutting, joining and shaping steel and other materials using a range of specialised tools.

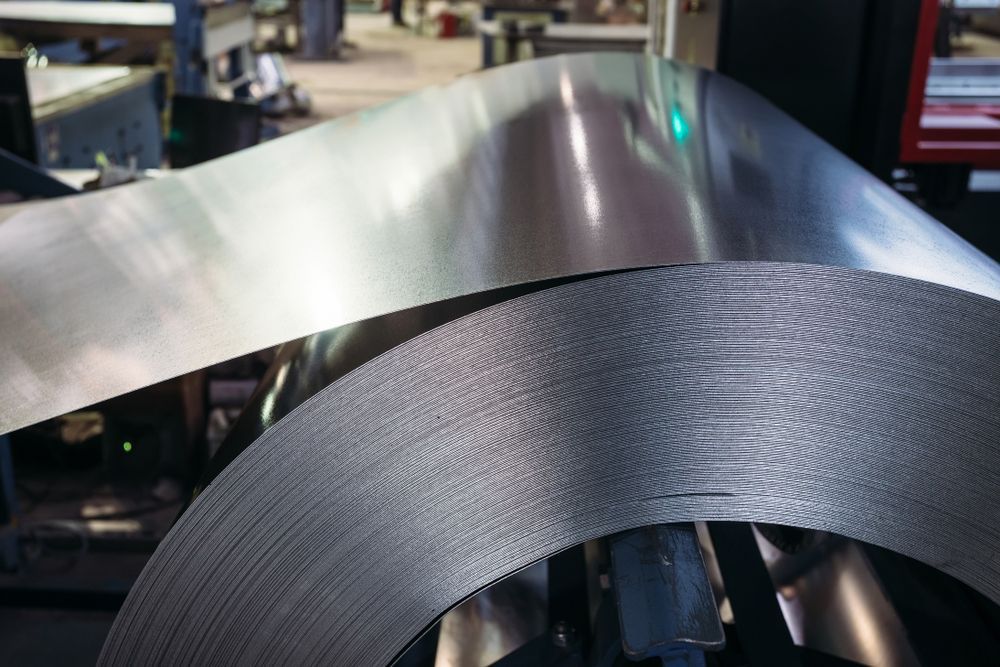

Rather than assembling an end product from ready-made components, steel fabricators create custom and stock products from semi-finished or raw materials.

Steel fabricators work on a wide range of construction projects of all shapes and sizes, from building bridges to fixing machinery. Steel fabricators are often hired to work underwater on oil rigs, support industrial projects and construct steel frames for buildings.

Rather than assembling an end product from ready-made components, steel fabricators create custom and stock products from semi-finished or raw materials.

Steel fabricators work on a wide range of construction projects of all shapes and sizes, from building bridges to fixing machinery. Steel fabricators are often hired to work underwater on oil rigs, support industrial projects and construct steel frames for buildings.

What Skills Does A Steel Fabricator Need?

Steel fabrication is a dangerous and highly specialised profession that requires several special skills, such as:

- Welding

- Taking precise measurements

- Knowledge of safety procedures

- Knowledge of equipment safety standards

- Basic maths and design skills

- Attention to detail

- Ability to work with your hands

Steel Fabrication Processes

Steel fabricators must be proficient in the following steel fabrication processes:

Welding

All steel fabricators are skilled welders. Welding is the process of applying extreme heat to a metal surface to melt it and attach it to another material. When the welded material cools, it solidifies and fuses with the other steel material.

Shot Blasting

Shot blasting is the practice of blasting sections of steel with small steel beads to eliminate any impurities and prepare the material for fabrication. Shot blasting creates a clean finish for steel fabricators to commence welding and prepare the material for painting.

Shot blasting is essential in a wide range of industries, including shipbuilding, construction and assembling steel structures such as tanks, silos and pipelines.

Shot blasting is essential in a wide range of industries, including shipbuilding, construction and assembling steel structures such as tanks, silos and pipelines.

Coating

For aesthetic and practical purposes, steel often needs to be coated. Galvanisation, for example, is a common process that coats steel with zinc to prevent corrosion.

Architects may also request custom looks and colours for steel, which needs to be coated with paint at the end of the fabrication process.

Architects may also request custom looks and colours for steel, which needs to be coated with paint at the end of the fabrication process.

Cutting

Cutting, as the name suggests, is the process of cutting steel into sections before commencing fabrication to make the material easier to work with or more suitable for bespoke purposes.

Steel is cut using several different techniques, such as circular saw cutting, plasma cutting and flame cutting.

Steel is cut using several different techniques, such as circular saw cutting, plasma cutting and flame cutting.

Contact Our Experts

At HardRok Engineering, we offer a wide range of fabrication and welding services for industrial, construction and mining businesses. To learn more about our services or to request a quote, give our friendly team a call on 07 4749 1770 today or fill in our online enquiry form here and we'll get back to you as soon as we can.