Common Issues with the Steel Fabrication Process

Steel fabrication seems like such a

standardised, mechanical process that it's probably hard to imagine that there is a right way and a wrong way to do it or that your choice in manufacturer will make a difference. That's not always true, and there is more to consider than just price when it comes to choosing a supplier for your structural steel.

So what can go wrong, and what should you watch out for when you're deciding who to commission? Let's take a look.

Poor craftsmanship

One of the most important decisions you can make is to choose a supplier that sticks to the latest industry standards, has a happy customer base and a commitment to upholding high standards in all that they do.

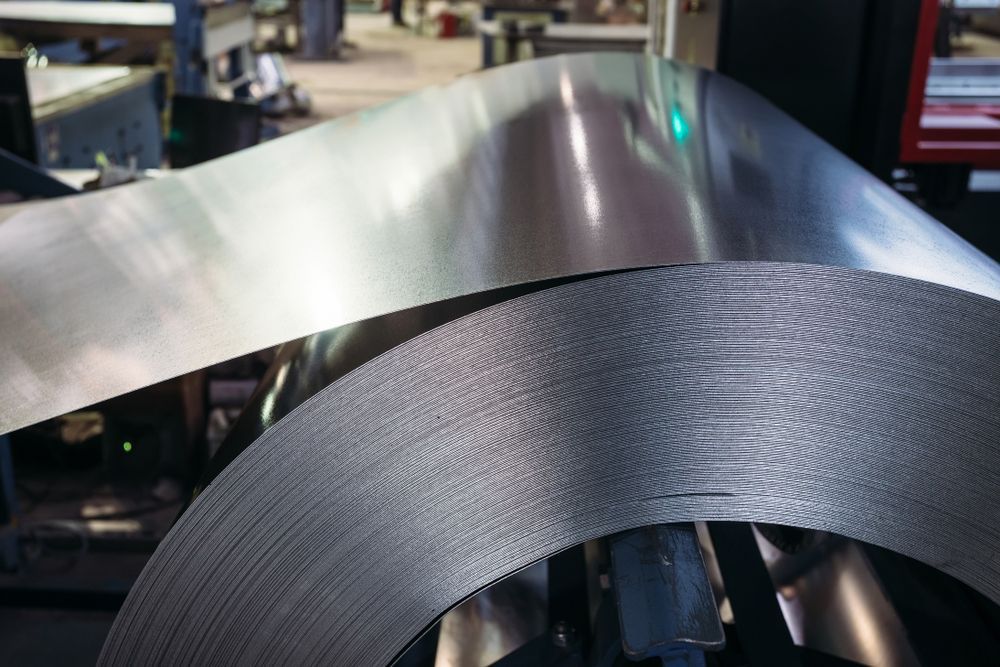

On and under the surface

More concerning can be problems you can't necessarily see on the surface. Dust, oil, industrial adhesives, iron particles and many other contaminants can find their way into scratches or even the fabric of the steel itself, leading to structural weaknesses and flaws that can corrode and even cause failure.

Lack of experience

It's always a good idea to use a supplier who can demonstrate their experience in handling large or complicated jobs before you start to avoid disappointment down the line.

Choose the professionals

At HardRok Engineering, we have the skills and experience to deliver projects of all sizes and complexities in steel fabrication, with always the highest levels of commitment and details as standard.

Our experienced steel fabricators are highly trained and conscientious enough to avoid those minor mistakes that can build up to more significant problems and handle those tricky or fiddly parts of the job that others can get wrong. We also invest in the best and most advanced fabrication equipment maintained to the highest standards so that our work is never second best.

Need steel fabrication done the right way?

Get in touch with HardRok Engineering on

07 4749 1770 or email us at

admin@hardrok.com.au today to find out how we can help.