Things to consider when using Stainless Steel Underground

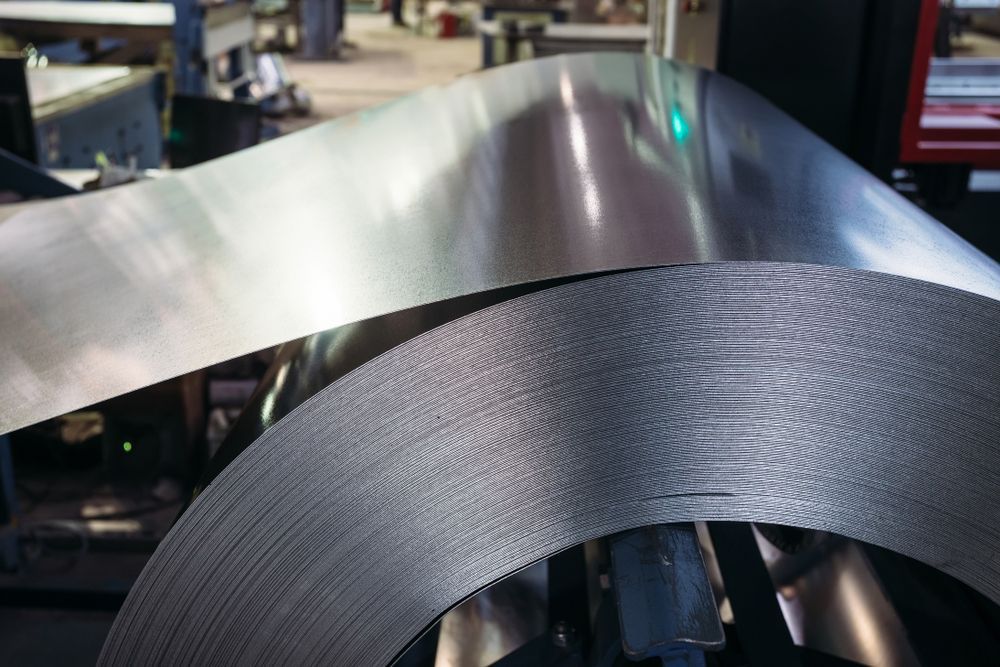

As a highly industrial material, stainless steel has many benefits, but there is a range of different factors to consider when applying this material to underground use.

So, we have put together the following guide on what to consider when ordering

custom steel fabrication in Mount Isa for your next project.

The strength of stainless steel

For underground use, it is important to consider the strength of the material you use.

Stainless steel is usually the more reliable option compared to other materials such as copper and polymer.

This is because copper and polymers are more susceptible to rust, making them weaker.

Stainless steel is a much stronger, heavier material made from alloys such as chromium and nickel, and for underground use, it is important to be able to rely on the sturdiest material available to keep you safe, above all else.

The different types of stainless steel

As with other metals, there are different types of stainless steel, and it is important to understand the properties of each type and their suitability for underground use. Our experts can assist you with choosing the right stainless steel for your needs.

The three most common types of stainless steel are austenitic, duplex, and super duplex.

- Austenitic steel is commonly used underground where the presence of water is likely, such as in pipes.

- Duplex steel has shown good resistance to cracking as a result of corrosion and is widely used in the chemical processing and transport industries.

- Super duplex steel is more capable of resisting corrosion from acid and chloride, and so is commonly used in the oil and gas industries.

The pH value of the surrounding soil

The area in which you are inserting the stainless steel

It is important to consider the underground environment in which you are inserting the stainless steel.

This is a factor that has the potential to weaken the stainless steel used underground as it can be a conductive material.

Although its propensity for this is poor due to the heavy nature of stainless steel, it's still a factor that needs to be taken into careful consideration.

HardRok Engineering is located in Mount Isa and services the Northwest Queensland and Northern Territory areas.

For more information or queries about our custom stainless steel fabrication in Mount Isa , contact our friendly and professional team today.